While many people associate superchargers with hotrods and muscle cars, there’s no reason why your MG or Triumph can’t enjoy the same benefits.

Supercharging has long been a part of the British car scene. From factory-built Blower Bentleys and supercharged MGs of the 1920s and 1930s to aftermarket offerings from Judson, Marshall, Shorrock, Wade and others in the 1950s and ’60s, many British cars have relied on force-fed power. It only makes sense that Moss Motors is reviving the tradition of supercharged British cars.

A few years back, Moss came out with an aftermarket supercharger kit for the MG T-series. Similar in appearance to the Marshall units available in the past, the Moss kit featured a modern Eaton supercharger for higher efficiency and better drivability. That kit has evolved into a line of bolt-on supercharger kits for many of the newer favorite models, including the MGA, MGB, TR6, TR250 and 1275cc-powered Sprites and Midgets.

Supercharging Basics

Before we get into the details, let’s discuss the basics of supercharging. Using an old analogy, an engine is basically a pump. It takes in a mixture of air and fuel, pushes out exhaust gasses, and makes power in between. If the engine can inhale more air/fuel or exhale the exhaust gases more efficiently, then it’s going to make more power.

Traditional ways of increasing the pumping capacity of an engine include cylinder head porting, camshaft changes and exhaust improvements. Each of these methods gives the air/fuel mixture and exhaust an easier path to follow—sort of like leading a horse to water.

With supercharging, you can actually make that horse drink. The supercharger is a high-volume, low-pressure air compressor that simply forces a larger air/fuel charge into the engine. Once that charge is burned, it’s got no choice but to force itself out through the exhaust.

This all sounds too good to be true. It is. Supercharging has some inherent side effects that need to be addressed. Number one is heat. Compressing the air/fuel mixture and forcing it into the engine causes much more induction heat than you’d get in a normally aspirated engine. This heat can cause all sorts of problems, but the worst is a higher incidence of detonation (pre-ignition, also known as knock). Another problem is the parasitic power loss needed to drive the compressor. It takes a fair amount of power to spin the belt-driven compressor, so a supercharger’s efficiency is paramount to its performance.

Historically, supercharging has enjoyed periods of dignity and disgrace. The years of high interest in the 1920s and ’30s were followed by some lulls. Supercharging saw a resurgence in the 1950s and ’60s, followed again by another long, empty period until the mid-1990s. Armed with computer-controlled, fuel-injection systems and precision manufacturing techniques, superchargers have again been embraced by automakers and the aftermarket alike.

On to the Details

Obviously, British classics don’t employ modern fuel-injection systems, but these machines can take advantage of the well-built, long-lasting superchargers installed on other types of engines. Eaton superchargers are used in many original-equipment applications including those from Jaguar, Mercedes-Benz, Ford and GM. They’ve also become a staple in aftermarket kits for Miatas, Hondas, Toyotas and others.

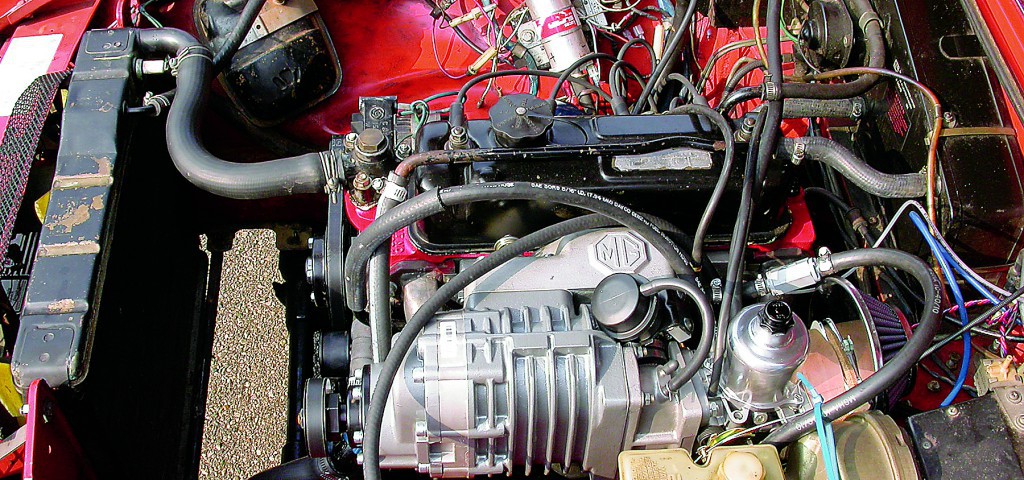

Moss has taken Eaton’s smaller models and integrated them into comprehensive kits that include every nut, bolt, hose clamp, and component necessary for installation. These kits contain the supercharger itself as well as a specially cast intake manifold, air filter, multi-ribbed serpentine drive belt system and brand-new carburetor—an SU unit in most cases.

Depending on the application, the kits also include new accelerator and choke cables, a water pump, a fuel pump, an alternator and cooler spark plugs. An installation manual is a critical kit component. All that’s needed to finish the job is an afternoon in the garage and basic hand tools.

Installing an aftermarket supercharger might sound like a daunting task, but Moss has already handled all of the heavy lifting. In addition to the supercharger itself, their kits feature every component needed, from a new carburetor to all of the associated hardware. To perform the installation, you’ll only need a free day and some basic hand tools.

Easy Installation

To show how easy is it to install a Moss supercharger kit, the following example demonstrates the process on a 1978 MGB. Remember, start with a car in good running order; the supercharger won’t magically fix a worn-out engine.

The installation process starts by removing the stock carburetor (and exhaust manifold if the car still has the single Zenith Stromberg setup), plus the radiator, water pump, alternator and lower crank pulley/harmonic balancer.

Then the new parts are installed: Replace the balancer with the lower pulley that has grooves for the multi-ribbed belt, then put in the new water pump and pulley. The next step depends on the car: For chrome-bumper machines, install a new alternator and pulley; for rubber-bumper cars, fit only a new alternator pulley. Next, install the supercharger along with a new exhaust manifold or header if necessary.

This brings up a step that needs a little extra attention, as there are different flange thicknesses for various exhaust manifolds and headers. These flanges meet up with the intake manifold flanges at the mounting points, so alignment is critical to avoid leaks. To match the thicknesses of these parts, Moss includes shims in the kit.

Once the supercharger is mounted, install the belt and its tensioner. Then reinstall the radiator and follow Moss’ instructions to cut and modify the lower hose, rerouting it with the pieces included in the kit.

After installing new accelerator and choke cables, hook up the lines for the fuel, vacuum, PCV and anti-run-on systems before bolting on the air filter assembly. Once everything is installed, you might need a timing and idle-mixture adjustment. Then take it out for your first drive.

More Power

More Power

Stock, single-carburetor, rubber-bumper MGBs usually peak at a little more than 50 horsepower at the rear wheels. The Moss supercharger kit can immediately bump that figure up to 90 horsepower—along with a nice increase in torque in the meat of the powerband.

What about real-world acceleration? That’s where the big gains are apparent on our MGB, as its zero-to-60 times dropped from 14 seconds to 10. On the highway, the car can now easily run with traffic and pass cars with overdrive still engaged.

Driving manners are the same as before: The car still starts, idles and behaves like a normal MGB, all without overheating or crankiness.

In short, the Moss Motors superchargers have allowed some of our favorite classics to thrive in today’s world—all without any downside.

Moss Motors Supercharger Lineup

1275cc Austin-Healey Sprite

1275cc MG Midget

MGA

MGB

Triumph TR250

Triumph TR6

Adapted from a Classic Motorsports story written by Carl Heideman

'Force-Fed – Bolting on a Moss Supercharger Kit' have 6 comments

October 1, 2012 @ 1:51 pm bob

Hello I have one of these kits fitted to my MGA (it has a B engine with O/D gear box) and has been going realy well for the past few years. But I have a problem. No fuel seems to be getting to the carb on some occasions. I have changed the pump. If you take the pipe off the carb it’s pumping well. It seems the carb is telling the pump no petrol needed. I have removed and checked carb all looks OK. I am going to strip the carb again. Would a high pressure pump work better? It is not anything to do with getting hot as it will do it when cold. Any ideas? Thanks, Bob

July 22, 2013 @ 6:51 pm Ray

the crank damper is there for a purpose …. it can’t be just left off … how can it be retained with these kits?

July 24, 2013 @ 8:10 am stuursmad

A reply from Blaine at Moss Tech Services:

The harmonic balancer, or dampener as it is often called, is designed to smooth the operation of the engine at low RPMs.

A classic four cylinder engine fires in the order of 1,3,4,2. Those four firings are spread over 720 degrees (two revolutions) of operation. As the pistons are on their compression stroke there is a force fighting the rising piston. That can slow the piston down. A piston that is in its combustion stroke, will try to accelerate the piston.

Whatever happens to the piston impacts the crankshaft.

We get an attempt to slow each of the four pistons for every 720 degrees. We also get an attempt to accelerate each of the four pistons for every 720 degrees. This creates a deter-push sensation. On a tiny level, the crankshaft actually slows and accelerates in pulses. A four cylinder engine spinning 900 RPMs will experience this cycle 1800 times per minute. It is felt (if at all) as a low level vibration. At higher RPMs it becomes a moot point. The crank shaft has enough inertia to sail right through the deter-push cycles.

The secret to smoothing out the low RPM vibration is also inertia. “An object in motion is inclined to stay in motion unless operated on by an outside force.’ A heavy weight is mounted on the front end of the crankshaft. A heavy flywheel and a clutch assembly are mounted on the back end. When a piston tries to deliver a deter or push pulse to the crankshaft, the inertia the crankshaft has allows it go resist being slowed or being accelerated. This helps the engine runs smoother at low RPMs.

Some automotive applications carried this a step further. They put the weight in a heavy ring on the forward end of the crank shaft. The ring and the crank hub are concentric. (Although distinct, they share the same point of center.) A rubber-like material is used to bond the our weight to the inner hub, while absorbing vibrations. This is a true dampener.

Now, we know we can use inertia to dampen the low RPM vibrations of a reciprocating motor. Let’s play with it. Does the damper have to be mounted on the crankshaft? No. In the case of an engine with a number of accessories feeding off the crankshaft for power, those accessories dampen. An alternator, a water pump, a power steering pump, an air conditioning compressor, and yes… a supercharger all serve as dampeners. The belt(s) we use to carry power from the crankshaft to the accessories serves the same way the rubber-like absorber serves the concentric weight and hub on some older engines. Since the supercharger’s internal rotor group weighs more than the a harmonic balancer weighs, we get a nice dampening effect by supercharging.

Do want to play with this?

Some performance drivers install light weight aluminum flywheels on their engines.

What will that do to the smoothness of the idle?

What will it do to the engine’s ability to spool to high RPMs quickly?

Answer:

In the absence of the weight a heavy flywheel would have, some dampening is lost. It will not idle quite as smoothly.

Not having to drag that weight when she is trying to spool up means she will spool up to high RPM’s faster. (That’s why he installed it.)

Blaine Graham

Tech Services

June 4, 2014 @ 8:41 am Charles R Wiggins

About three years ago I installed a Moss supercharger on my MGB LE. It starts easily and the acceleration is fantastic but it will not cruise or idle smoothly and is very rough on deceleration. It gets very annoying on a drive of any distance. I have had two different mechanics look at it without any improvement. Others I have ask just appear puzzled. One did mention something about a “bypass”. Can you offer any solutions?

June 20, 2014 @ 10:48 pm TShortt

I was told by a questionable source that my 1971 MG needed a Drivers Side wiper transmission. I have searched the internet for hours and have yet to come up with anything. Does it even exist or can someone help me find it perhaps under another name.

May 30, 2017 @ 3:23 pm Steve Ball

The windscreen wipers are worked by a rod with lots of rings machined into it that is slid backwards and forwards in a tube past a little cog-wheel that engages with those rings. The little rings make the cog spin backwards and forwards. The cog has a short shaft running through it, out through th bodywork and the other end of it has the splines where the wiper-blade fits. This splined stub shaft and cog and tube assembly could be called the wiper transmission as it’s a tiny gearbox=transmission I suppose. Parts suppliers seem to call it a wheel box though, not a transmission. See item 16 here http://www.moss-europe.co.uk/windscreen-wiper-system-roadster-gt-1967-80.html item 11 is the long cable with its two straight section where you can see the little ‘rings’ I described.