Bryan Miller has spent the past 10 months restoring a symbol. The black 1962 Mark II MGA given to him by his father is more than just a rusted heap of metal. As anyone who gets involved in the restoration process can testify, it can be a spiritual journey. Miller had already discovered this when working on other projects—his 1971 split-bumper Camaro, a 1963 GMC, a 1957 Ford F100—but he had never taken on something like this, a project that also represented his relationship with his father.

Miller’s father bought the car in 1965 from “a kid” in Pennsylvania, who had purchased it from a gentleman in Florida. Miller believes the MGA came from Florida and that his father was the third owner. During a 1983 winter, the MGA was parked indefinitely, closing a chapter in Miller’s life. “My father and I were not very close,” Miller says. “But I remember the car and the times we had in it when I was younger.”

In November 2001, Miller’s mother died of cancer. He went to Pennsylvania to be close to her and help tie up the loose ends. Right before he left to return home, Miller’s father handed over the keys to the MGA, which was symbolic in itself, considering the car had to be towed back to California. During the trip, the tarp somehow ripped off all the emblems and the license plate frame, an occurrence that Miller hadn’t foreseen, but he didn’t let it faze him.

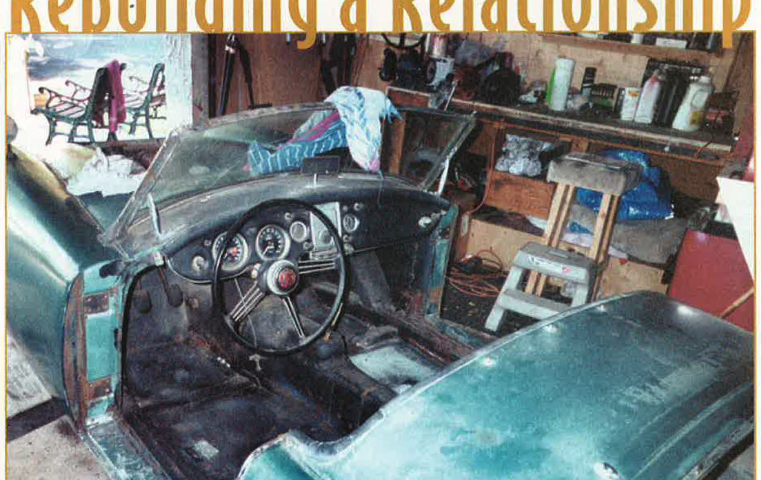

The car sat in Miller’s garage for about one month before he decided to take the passenger fender off to see just what he was working with. “What I discovered was a lot of rust,” Miller says. “I really did not think the car was salvageable at this point, and I wanted to send it to the junkyard. But I got my friend Bryan Lacasse to take a look at it. He has restored old cars before and said we would be able to save the MGA.” The use of the word “we” was important to Miller, as he says he couldn’t haven taken on the project by himself.

About two weeks later, Miller and Lacasse were sitting in the garage and checked to see if the motor was frozen. “To our disbelief, it was not,” Miller said. “We cleaned up the points, added water and a battery, and the car started without a miss. I could not believe what I saw and heard.” Two days after this miracle, the pair began work on the frame. Most of the inner panels were full of holes from the rust. The damage was so bad, in fact, Miller and Lacasse had to cut the car in half.

Encouraged by his friend Bryan Lacasse and the fact that the engine started on the first try, Miller began the process of taking the car apart only to rebuild it again.

Countless hours of blood, sweat, and tears later, the MGA was in many different pieces, a deconstructed puzzle of 12 parts. Miller and Lacasse took the frame down to bare metal, cut out the rust, welded new parts for the frame, and put the floorboard supports back into place. They then replaced every piece of suspension rubber throughout the drivetrain and installed new floorboards. The last items in the drivetrain that needed to be tackled were removing the engine, front suspension, and steering.

“Once we had removed the final things, we took the frame down to bare metal, repaired some of the frame, and painted it,” Miller says. “We were really lucky that we didn’t have to rebuild the engine, but we did replace every external engine part we could.” Once this chore was complete, the pair put the front of the drivetrain back together, taking one piece of the inner body at a time, cutting and welding the new pieces in.

When the frame was back in one piece, they started on the bodywork. Lacasse and Miller picked up the main part of the body and placed it on the frame. They then took the wiring diagram and installed the new wiring harness, put the radiator in, installed the oil cooler, put in all the fluids, and added a battery. They were finally ready to test for a spark.

When Miller cranked the motor, it started right up. “It was such a wonderful feeling,” Miller said. “It really felt like it was starting to fall into place.” But not all was perfect. “The clutch bled okay, but the right front caliper blew a seal under pressure. We were not going to let that stop us from taking the car for a ride. Bryan was the brake man (using the E-brake) and we drove the car for about two to three miles.” At this point, the only problems Miller was working on were the right front caliper and a mysterious leak in the front of the car.

Miller says he should complete the job by December 2002. The most challenging part of this job has been getting all the body parts to line back up. Miller is thankful for his welding skills and patience, as well as for Lacasse’s help. Taking the MGA apart and putting it back together again has helped Miller reconnect with his father in a tangible and rewarding way. As for the feeling he got when he first had the chance to drive the MGA (his first time ever driving it), Miller says, “It was even better than I thought it would be.”

'Rebuilding a Relationship' has no comments

Be the first to comment this post!