I shoved a stick in the hole where the screw should’ve been in the thermostat housing. That took care of the leak for a good six months.

It was 1975, and I was 17 years old. By the way, I still own the TD!

-Harry Horton

God bless British cars, right, Harry? You’ve given new relevance to the term ‘Shade Tree Mechanic.’ Our thanks to everyone who sent in their savvy solutions. If only we had room for them all.

Oh, and hey Tom Robbins, we found your Can o’ Beans…

~Editor

In 1963, I owned a 1956 100-4 Austin-Healey while in the Air Force. After a home leave, I headed north to return to base but came to an abrupt stop around Bakersfield, CA. The fuel pump had quit. The SU’s click-click was silent. It was nighttime and I had to be back on base for an early shift as a radar tech, so spending the night in Bakersfield was not an option. By removing the battery hatch, I was able to access the fuel pump and remove the cover over the points. By hand activating the points I was able to get the gas flowing again and I proceeded to drive the remaining 250 miles with one hand on the steering wheel and one hand pumping gas. I found new points the next day.

–Gary Cash

Driving to the 6-Pack “Trials” in New Jersey, my TR6 suddenly quit on the Merritt Parkway in pouring rain. A fellow TR6 driver stopped and noticed there was no fuel coming from the fuel filter. Getting skinned knuckles and wet, we changed the filter by the side of the busy road, and the car restarted. Success! Or so we thought.

Arrived in south Jersey and the car quit again at the hotel parking lot. We discovered there was an extreme vacuum condition in the tank, which when released, would allow the car to run for a while. For four days I had to jump out every 50 miles and open the filler cap to prevent the car from starving for gas.

I bought scissors and gasket material and, while sitting in a hardware store parking lot, fashioned a “vacuum release” gasket for under the filler cap. I drove 200 miles home without incident.

The prior owner had removed the vapor separator on the fuel tank that sends gasoline fumes to the charcoal canister. Without it, liquid fuel would clog the line; neither the vapor recovery system nor the fuel pump could clear it. I now carry the homemade gasket with me as a “field fix” just in case.

–Bart Bauers

While racing my ’51 MGTD at New Jersey Motorsports Park, I came in after a session to find oil splattered all over the front of the engine. The generator belt tension adjusting bolt came loose, the generator fell onto the timing cover and the fins of the generator cooling fan contacted the timing gear cover, grinding a gaping hole! The crew thought “we’re done,” but I said “no way!” First, I removed the damaged fan from the generator then scrounged up a Coke can, cut and shaped a piece of it to cover the hole and JB welded it in place after a thorough cleaning. Leak-free for the weekend and the rest of the season! We joked about the “MacGyver fix” the whole weekend.

–Frank Filangeri

In the mid-1970s I was working for a car dealer who sold Jaguar, MG, Triumph and, uh, Fiat. Several of our Fiat 124 customers had problems with their wiper motors, as they tended to overheat and melt the plastic brush holders. We couldn’t convince the Fiat service rep that this was a warranty issue, though, as he insisted they overheated due to “owner abuse.” One morning I was driving a loaner 124 sedan to work in the midst of a wet, slushy snow storm. Giant soggy snowflakes splattered against my windshield and stuck there, blocking my vision until the wipers shoved them aside. That’s when the motor overheated and the wipers stopped dead. I still had at least 30 miles to go.

I disconnected the wiper linkage from the motor so the wipers moved freely, took the laces out of my work boots, tied one lace to the driver’s side wiper arm and ran it through the vent window on the driver’s door, and tied the other lace to the passenger’s wiper and ran it through the passenger’s vent window. I then pulled my belt out of my trousers and tied it to the laces so it was stretched between them inside the car. By grabbing the belt with one hand and pulling it back and forth I could make the wipers sweep across the windshield. As luck would have it the Fiat rep was in the showroom when I pulled into the lot, dragging the wipers back and forth with my bootlaces. He had trouble blaming that wiper failure on owner abuse.

–Steve Tom

Back in the sixties, I learned a lot about repairing cars, because I was quite good at tearing them up. I spent more time under them than in them. On one occasion, I lost oil pressure on my way home. Fortunately it was all downhill and I coasted home without lunching my engine. I quickly discovered that the oil drain plug had fallen out. I needed the car to get to school the next day, and found a temporary solution in the refrigerator…a carrot. After a little carving, I “threaded” it into the hole. It not only got me to school but home again as well. Needing a more permanent solution, I discovered that a spark plug had the exact same threads. I forget how long I drove around with the spark plug in my pan.

–James Gorman

On a Sunday afternoon several years ago, I saw a nice MGA with the bonnet up in my neighborhood. After chatting with the worried owner, it appeared the pulley on his generator had one side break off. I offered to let him park it at my house while he arranged for a flat bed tow.

After a short drive to my house on battery power, I proceeded to remove the broken pulley under the concerned eye of the owner. Rooting around in my Jensen Healey spares, an old alternator was located and the pulley removed. The shaft size was close and the overall diameter was larger. I bolted it on and adjusted the drive belt, which now had to travel through a “Z” since the Jensen pulley was further out on the shaft. It looked ridiculous and even a bit stupid since the pulley didn’t center properly either, but the generator was turning. The owner thanked me and headed the 40 miles home to San Francisco over the Golden Gate Bridge.

A few days later I found two bottles of wine and a nice card on my doorstep. He made it!

–Kurt Housh

I decided to have a local speed guru re-curve my ’71 TR6 distributor in an effort to extract just a wee bit more power out of my very tired straight six. After the mandatory two-week wait, I eagerly reinstalled the distributor and hit the road. For 10-15 miles I was impressed with its new vim and vigor right up until it died on the freeway in the fast lane. What the heck? Fuel good, no spark! Pulled the cap, cranked and noticed the rotor remained motionless. Pulled the distributor out and was shocked and bemused to see the drive gear sitting an inch or two below where it was supposed to be. No dowel in the shaft! I had removed said dowel in an attempt to help the tech, and the little car remained steadfast until my exuberant driving style worked the gear loose. So I needed a dowel. Not to fret, a piece of wood might work? Searching alongside the freeway I spied a Popsicle stick. Whittled it down and jammed it in, cranked the motor to set the distributor at the #1 cylinder, loosely set the hold-down clamp and fired it up. Adjusted the timing by ear and hotfooted it back to reclaim my dowel. All in all, a great time.

–Ken Brinkley

Two years ago I decided to do a frame-off restoration on my ’72 TR6. Having limited space and being my first frame-off project, I started to investigate ways to separate the frame and body and to store each piece as I did the restoration. Through watching YouTube videos, conversations, web searches and magazines, I found everything from using jack stands to a $3,000 lift. None of these really impressed me or fit my budget. Also, space was a consideration for storage of the body and working on the chassis. So after all this I decided to build my own “lift” which would allow me to separate the body/frame and still have work and storage space in the same footprint. So, for a few hundred bucks, four block and tackles, eight eyelets and an afternoon of my time, I built my lift. It gave me everything I needed: affordable, space, storage and easy access to the body for repairs. Presently, I am close to setting the motor/transmission back into the rebuilt frame, completing work on the frame and then rolling the chassis under the lift and lowering the body onto the frame. Wish me luck!

–Jim Shumaker

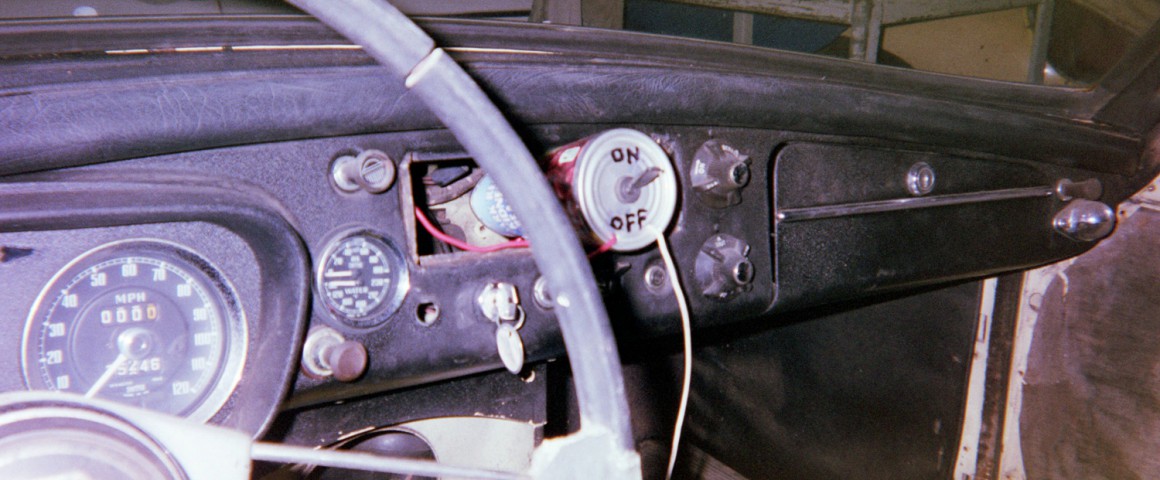

It was my first MG. Everything was new to me. My brake lights weren’t working and I was given a Fix-It ticket from the Highway Patrol. I rigged up a toggle switch to a can of kidney beans, hotwired to the brake lights. Went down to the station and they signed off on the ticket.

–Bill Riggs

Heading home one afternoon in the 1960s in my ’54 100-4 Healey. I turned onto a lesser-traveled road with an immediate steep uphill. Halfway up, steam billows from the front so I pull over. I had blown a fan belt and overheated. I coast backwards fast enough to turn around and then continue down the hill to a gas station at the intersection. My girlfriend, now my wife, is somewhat frantic.

The attendant sees my Healey and laughs heartily, doubting very much that he has anything that will work. But I can look. After pawing thought about 50 belts on the rack and in the back corner, I find a couple maybes. I size them up and select one, borrow tools, get it installed and add water.

Asking about cost, he smiles, says, “Five bucks ought to cover it.” I gladly forked over the money and head for home. The belt was for some diesel tractor-trailer accessory. Who knows what you might find in a dusty corner of some old service station.

My girlfriend was convinced we were stranded for good and needed to be towed home. Not today though, even if I needed to use her pantyhose for a belt. I never mentioned that trick to her.

Great fun for an immortal 17 year old.

–William Kollar

'Rigged Stories' has no comments

Be the first to comment this post!