Today we have a set of ignition points in our shop. He’s agreed to let us ask him a few questions.

Mr. Ignition Points, can you tell us what your job is? What do you do in our car?

“I tell the coil when to fire a spark.”

Is that a hard job?

“It can be. When your four-cylinder motor is spinning 3,000 RPM I have to command the coil to fire 6,000 times per minute. And… I have to make sure every one of those firings is exactly on time. So, I guess you could say I’m pretty busy. It’s a lot of responsibility, but I like my job. I’m right I the middle of all the action.”

Why is being on time so important?

“If the coil is firing the spark plugs early, that can lead to detonation and harm to the engine. If the coil is firing the spark plugs late, the motor will lose power. It would feel like you are towing a boat.”

Can you tell us, in simple terms, how you do your job?

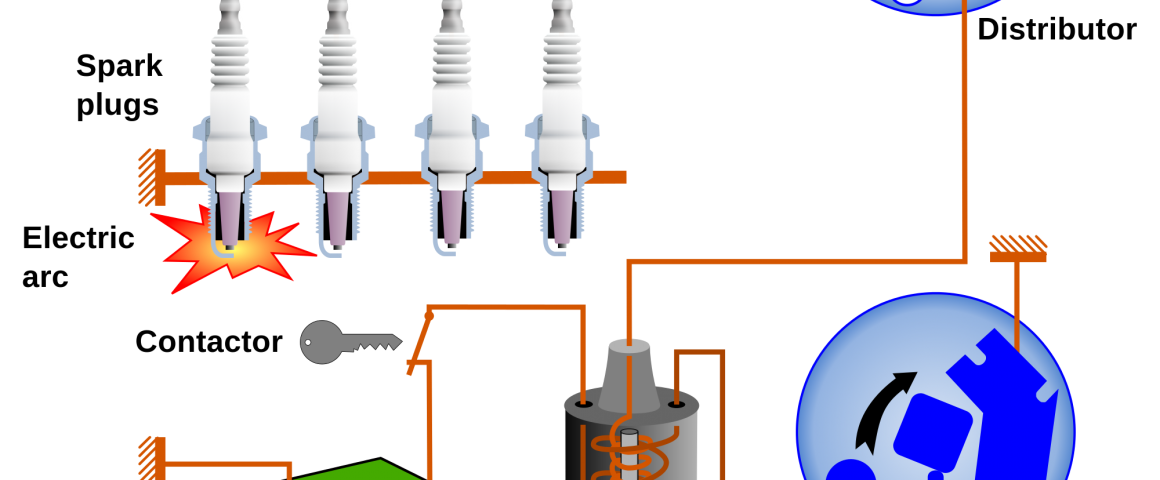

“Sure. It’s really not complicated. When you turn your key on, electricity goes to one of the two small terminals on your coil. Inside the coil there is about a million miles of wire. That wire is wrapped around and around inside the coil until the end of the wire comes out the other small terminal on the coil.”

Forgive me for interrupting, but are you saying the small terminal on one side of my coil, and the small terminal on the other side of my coil, are two ends of the same piece of wire?

“That’s right. It’s a very long piece of wire.”

So, what happens when the electricity from our ignition switch goes to one of the terminals of our coil? I assume it must run through that long wire and comes out the other side of the coil. Right?

“That’s right. Electricity travels at almost the speed of light. But, even at that speed it needs a moment to fill that wire with electricity from one end to the other. When the coil is full of electricity, the electricity can come out the second side of the coil and go to the distributor. That’s where I work.”

What do you do in there that makes the coil fire?

“I’m made of two contact points. One is connected to ground. The other is connected to that wire coming from the coil. When my points are closed, the electricity can flow from the ignition switch to the coil, through the coil, out to the distributor, to me, and then to ground.

“When I open my contact points, all that energy inside the coil suddenly has no place to go. It’s like somebody slammed the door of its escape. In layman’s terms, that forces all that energy to come out of the top of the coil in the form of one big spark.”

So, when you open and close, and open and close, the coil fires one time each time you open. Right?

“You’ve got it! When I’m closed the coil fills with energy. When I’m open, the coil has lost it’s preferred way to let that energy out, so it pushes it out the coil tower on the top of the coil.”

How do you know when to open?

“As you know, I work inside the distributor. In the middle of the distributor is a shaft that rotates. It’s very much like a camshaft. In fact, we call it the distributor cam. In a four-cylinder engine the cam has four lobes (high points). On a six-cylinder engine it has six lobes, etc. As the cam goes around, the lobes on the cam push my points open. When a lobe has passed, I am closed until the next lobe comes along. It’s all pretty simple.”

Do you work alone in there?

“Heavens, no. I’m a member of a terrific team. I work with some really solid guys. I work on the second floor. I share my workspace with the condenser. He’s my helper. He takes some of my work so I don’t get overloaded. Below the condenser and me is the first floor. The advance weights work down there. They advance my timing as the RPM’s go higher. Over my head the rotor is working on the third floor. He sits on the top of the camshaft. When the cam turns so that a lobe is facing me, the rotor is pointing toward the corresponding terminal that connects the correct spark plug wire to the correct spark plug. He works alone which is probably a good idea. He’s always racing around in circles up there.”

If you guys work under the distributor cap it must be dark in there.

“You might think so, but no. I’m opening thousands of times each minute. Each time I open, the coil fires once. That’s thousands of firings per minute. All those firings are sent to the rotor over our heads. As the rotor spins around, sparks are flying out the end of the rotor and jumping to the terminals that live in the ceiling. Each firing goes to the correct spark plug at the correct time, and lights up our workshop. It’s actually pretty and amazing.”

How long do you have to work before you can retire?

“That’s a hard question to answer. We don’t retire after a specific number of miles or a specific amount of time. We retire when we are too tired to do our job correctly.”

Do they have a party when you retire?

“It’s not a party. It’s kind of a ceremony. You might call it a changing of the guard. On the day that I am to be relieved, the distributor cap and rotor are removed. The engine is turned by hand (in the direction it rotates while running) until one of the cam lobes is facing me and the gap is wide open. Then I am unscrewed from my place.

“My replacement is put into my place and the screws are reinstalled. The screws are not tightened. They are just snug. When I am relieved and the new guy is in place, the Master of Ceremonies calls out “POINT GAP?” A moment later the point gap for the new points read aloud from the sacred Shop Manual. It can vary but it’s usually about 0.015 inches.

The honor guard marches up with a feeler gauge that’s exactly the right size. The new points are moved until the gap between the new points is at the specific gap. Then the screws are tightened. They usually use the feeler gauge once again to make sure the new points didn’t move while the screws were tightened. The rotor is restored to its place. The distributor cap is restored to its place. The ceremony is over.”

How long does the points changing ceremony last?

“If the screwdriver and the feeler gauge are present when we start, the ceremony lasts about ten minutes. It’s good that it’s so quick and easy, because everyone wants to take the new points out for a test drive.”

Search the Moss Motors YouTube Channel for videos related to this topic—and much more!

• Detonation, knocking, pinging: What is it?

• How to: Test your ignition system … Part One … Part Two

• How to: Test your ignition coil

'Talking Points' has 1 comment

July 6, 2016 @ 3:33 pm Abram Was Here

Dang Mr. Ignition Points! You keep busy! Pretty Amazing!