By Warren Mann

“Hey Jon, just a heads up… six months till the Invasion!” On a cold March morning, I fired off a text message to my cousin, reminding him it might be a good time to dive into one of his Healey projects so that he’d be ready for the long drive to Stowe, Vermont, in September.

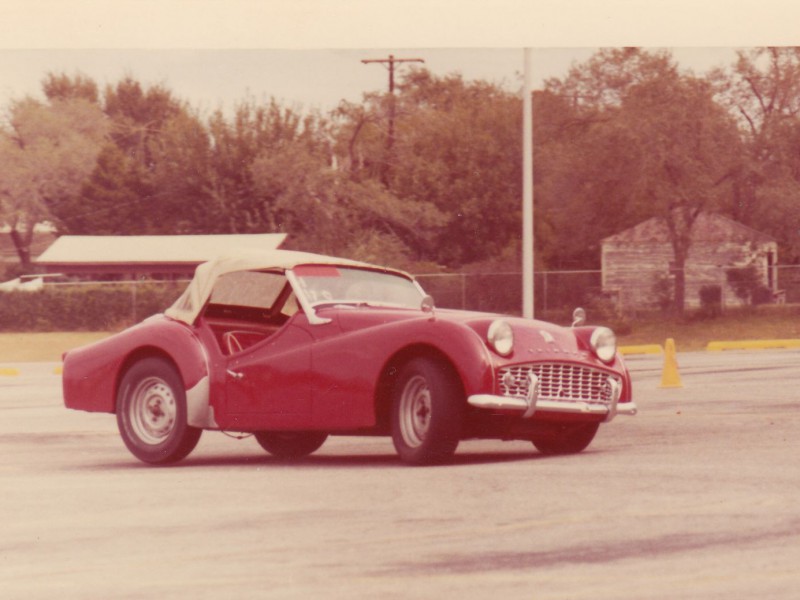

The British Invasion is one of our “not to be missed” old car events. It’s a great weekend that kicks off Friday morning when Judy and I climb in our 3-wheel Morgan and caravan from Southern New Hampshire with Bob Cushman and JR, driving one of their perfect ACs. We meet the Worcester, Massachusetts contingent for lunch at a pub in Woodstock, Vermont. There is cousin Karla in her original California MGB, Wayne in his highly modified TR3 mounted on a TR6 frame, and Jon in his trusty Bugeye. We take back-roads through northern Vermont, and it takes us most of the day to get to Stowe. Friday night, main street is closed to traffic and lined up with British cars. A classic rock band plays live music, and with food tents and a beer garden it is a fun night. Saturday and Sunday, hundreds of British cars of every make and model line-up in a big field for hours of visiting with fellow owners, lots of car talk, tire kicking and parts scrounging. All said, my favorite part of the weekend is Friday’s drive to Stowe. The scenic roads of rural Vermont are ideal for putting little British cars though their paces.

Last year, the weekend concluded with Jon saying the front end of his black Healey 3000 was in dire need of repairs and his Bugeye had a stuck clutch. Either project could be time-consuming, as one thing so often leads to another, when working on little British cars.

“Hey Jon, just a heads up… three months till the Invasion…” I fired off a second text message early in the summer. Jon has a busy work schedule and a garage full of motorcycle projects, so it is understandable that almost a year slips by with no time found to work on the Healeys.

Summer came and went, and with just 3-weeks to go before Stowe, I sent off another text. “If you’re ready to crack into one of the Healey projects, why don’t I come down and lend a hand?” It’s always fun working with Jon. We have similar experiences keeping our British Cars on the road the past 45 years. We also tend to mostly think alike, and we’re able to solve problems and accomplish a good deal of work during the course of an eight or nine-hour day. “How about Labor Day weekend?” replied Jon. Saturday morning Judy and I packed the Harley and headed down to Jon and Janet’s place. He had already moved three motorcycles out of the garage to make room to work.

First, we removed the front body clip, rolled the engine hoist into position and set about hooking up a chain hoist to pull the engine and gearbox. Electrical connections and control cables were disconnected, the radiator was drained and removed, the engine unbolted from the motor mounts, the gearbox shifter and gearbox mounting bolts removed and Jon had already drained its oil.

By lunchtime we had hauled the engine, swung it onto a workbench to remove the gearbox, and then disassembled the clutch unit. “We should be done by day’s end!” Yeah, sure Jon, whatever you say. The clutch was stuck to the pressure plate assembly. After a few raps with a mallet, it freed itself from the grip of rust. The assembly had few miles on it and was not worn, it only needed to be cleaned up and polished with emery paper. We re-assembled the clutch, re-fit the gearbox and installed the engine back in the car.

One of the reasons we work so well together is that neither one of us insists that we know more than the other guy. We think things through, occasionally have conflicting opinions and differing solutions, but we respect the old adage: “two heads are better than one.”

I installed the radiator and Jon started hooking up the control cables. The throttle cable and the choke cable were both in need of replacement. I had suggested we borrow the parts off his square body Sprite that was stuffed in the back corner of the garage waiting on new floor panels. Jon reluctantly agreed.

Day Two

It was time for a test drive around the neighborhood. A large, new battery borrowed from Jon’s Healey 3000 easily spun the little four-cylinder engine over and it roared to life. We lowered the car to the ground, climbed in, turned the key and… now the car mysteriously refused to start.

We checked the fuel pump. Gas flowed fine to the twin SUs. However, pulling the plugs, we found no spark. Now we’re getting somewhere. Jon took off the distributor cap, measured the gaps of the points, and confirmed a spark arched across the faces of the points as they opened and closed.

Last fall, when our friend Cush couldn’t get his Healey 3000 to start, we found the issue was the plastic insulator (which I call the “Top Hat”) was not properly shielding the two wires inside the distributor from the post on the points. It was grounding out. With that in mind, I took a look at the insulator and saw that the nut to hold the two wires in place was completely missing. “That’s the problem!” I said. That nut could have shaken loose or never been installed during a points change years ago. By some stroke of luck, the car had run fine for many miles, but after a few years, the loose wires had picked up a little corrosion and were no longer making good solid contact. Jon fitted a nut in place and the car fired right up.

We were anxious to install the front body onto the car but knew it was wise to take a test drive first, as it is a real back breaker to work on the engine when the hood is in place. Down the driveway we rumbled, and out into the street for a test run. Jon grimaced and proclaimed that the brakes were dragging.

Back in the garage, we removed the wheels and the brakes. It was obvious that, like the clutch, the brake calipers had rusted and were not releasing. Jon also suspected that one of the brake line rubber hoses might be collapsed inside. I took off the first brake caliper and on the bench could see it was bound-up, but the brake pads appeared to be in good shape. I took out the pads and started to spray and clean up the caliper. Once the assembly was operating smoothly, with perfect timing Jon said, “I think I may just have some brand-new brake calipers here in the garage for the square-body car rebuild.” By this point, robbing parts from the square-body, had become a running joke. Even the wives were joining in. After a few minutes searching, Jon unwrapped two brand new brake calipers. I took one and started to install the cleaned-up brake pads into them. “Hey, I found brake hoses,” Judy said, “Let me look around. It would sure be nice if you had some new brake pads, too.” She shuffled through a box and opened a bag, “Here they are!” So we reassembled the front brakes with all new parts.

Bleed, bleed, and more bleeding. It takes a while to bleed the air from the brake lines when installing new parts. Soon the hose connected to the brake calipers stopped sending out air bubbles and we were done.

Jon and I climbed back into the car for another test drive. As we were backing out of the garage Judy screamed, “Stop! There’s liquid spewing out of somewhere!” We put the car back on the jack stands and I climbed under the back of the car. As soon as Jon turned the key switch, gas shot out from under the rear of the car. The rubber hoses leading from the tank to the fuel pump and from the pump to the fuel line– that runs to the engine bay, were very hard and we both suspected a cracked hose. We removed the four clamps and replaced the hoses. Judy turned on the ignition and it still leaked, but this time we saw the culprit. Gas was coming out of the seams of the fuel pump. Ethanol, upon disassembly we would clearly see, dissolved the rubber gaskets inside the pump.

“I have another low psi 12-volt pump that I use for pumping oil and fluids.” Jon said. It fit the mounting clamp of the old pump, but took some futzing around as the pump had larger hose fittings mounted vertical rather than horizontal. Without too much effort it worked.

We had taken up the entire day on projects that we had not anticipated having to deal with, but old cars do not like to sit idle and unused. After two days and 16 hours into the project, everyone was ready to call it a day. Jon and I were covered head to toe in brake fluid, gasoline, antifreeze, grease and grime. The day had heated up and we were both exhausted.

Day Three

It’s time for another test drive with the new fuel pump and new brakes. Then we can reinstall the body to the car. We roared across the countryside.

As the car warmed up and loosened up, it ran better and better, even with stale old gasoline.

We returned to the garage, reinstalled the front hood, our mission accomplished. And there were still two weeks to go before Stowe.

Although Jon loves taking projects to the last minute, persistence in conquering mechanical challenges is something we both seem to have in common. Two stubborn, Yankee-Swede, motorhead cousins. It must be in our blood.

'The Rude Awakening of a Dormant Bugeye' has no comments

Be the first to comment this post!